Home »

Freight / Goods Elevators

Freight / Goods Elevators

WHAT IS FREIGHT ELEVATOR, HOW TO CHOOSE A

FREIGHT ELEVATOR

Freight elevator is essentially designed so as to fulfill material handling

requirement of industry, building, hotel, car workshop etc. For a properly

engineered installation, the choice of freight elevator requires

consideration of such factors as volume and weight of material to be

transported and the method of handling like manual or trolley driven. Where

floor leveling accuracy is of paramount importance it would be sane idea to

install ACVVVF control in Freight elevator. Today freight elevator is back

bone of any modern industry and is able to find its place in Pharma,

Petrochemical, Telecom, Components, Garment, Cosmetic, Architects,

Construction and Hotel industries to name a few.

We at Beacon have various models of Freight elevators to choose from wide

variety of capacities and sizes and always attempt to customize our product

according to customer's requirement. Today for all modern industries it has

become imperative to have an efficient material handling system which would

directly cut down the overall cost(labour cost, standing inventory, storage

cost). Therefore benefits of having installed a freight elevator far exceeds

the initial cost incurred there upon.

Over the last decade Beacon has specialized the concept of vertical

transportation of material through its innovative techniques and designs.

One of the landmark achievement has been development of Flameproof Limit

Switches to provide our client with the elevator that is suitable for

hazardous area. Till date beacon has installed more than 40 flameproof

elevators working at different plant locations of top pharmaceautical /

chemical companies.

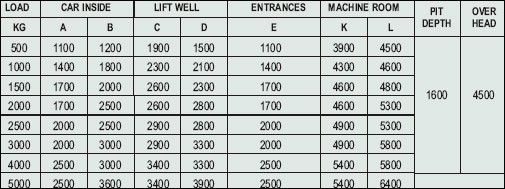

Freight / Goods Elevators - Minimum Civil Dimension

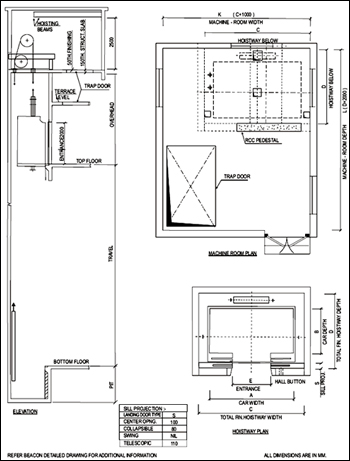

Freight / Goods Elevators - Sample Drawing

CLIENT’S SCOPE:-

- Construct the shaft (230mm brick / 150mm RCC Walls) and Machine Room

Slab (with Pockets) in accordance with our GA drawings.

- Mason with material for minor builder's work such as pocket cutting,

grouting, door fixing etc.

- Temporary power connection for erection & testing work.

- Scaffolding till the time of erection for about 30 days.

- Access to Machine room, Machine beams, supporting beams, pit ladder

etc.

- Power supply(415 Volts, 3 Phase,4 Wires with Neutral,50 Hz. & 230

Volts 1 Phase) near our control panel with MCB/JUNCTION BOX.